3D Printing Conductive Materials

Conductive 3D printing materials are revolutionizing additive manufacturing by enabling the direct integration of electrical pathways into printed objects. Unlike traditional electronics that rely on copper traces and precious metal contacts, conductive filaments and conductive polymers offer new possibilities for embedded electronics, smart devices, and functional prototypes. The resistivity of these materials is significantly lower than most filaments. First, let's look at available filaments for conductive traces.

Conductive Filaments:

Conductive polymers form the foundation of modern conductive 3D printing materials. These specialized thermoplastic composites combine traditional base polymers (PLA, ABS, TPU, PETG) with various conductive additives to create printable materials that can conduct electricity while maintaining structural integrity.

Key Advantages of Conductive Polymers:

Direct integration of electrical circuits into 3D printed parts

Elimination of post-processing assembly for basic electronic components

Reduced manufacturing complexity for electronic enclosures

Cost-effective prototyping for electronic devices

Compatibility with standard FDM 3D printers

Types of Conductive 3D Printing Materials

Carbon-Based Conductive Filaments

Carbon Black Filaments Carbon black represents the most economical option for conductive 3D printing materials. These filaments offer moderate electrical conductivity while maintaining good printability and mechanical properties. Carbon black conductive filaments are ideal for:

Antistatic housings and enclosures

ESD-safe components

Basic touch sensors

EMI shielding applications

Graphene-Enhanced Conductive Polymers Graphene-infused conductive filaments provide superior electrical properties combined with enhanced mechanical strength. These advanced conductive 3D printing materials offer:

Excellent electrical conductivity

Improved tensile strength

Better thermal conductivity

Enhanced chemical resistance

Carbon Nanotube (CNT) Filaments Carbon nanotube conductive filaments deliver exceptional performance when properly dispersed within the polymer matrix. CNT-based conductive 3D printing materials provide:

Superior electrical conductivity

Outstanding mechanical strength

Excellent durability

High-performance applications capability

Metal-Filled Conductive Filaments

Metal composite conductive polymers incorporate metallic powders to achieve higher conductivity levels:

Copper-Filled Filaments

Highest conductivity among readily available options

Approaching conventional electronics resistivity levels

Susceptible to oxidation at high temperatures

Higher cost and potential brittleness

Silver-Filled Conductive Materials

Premium conductivity performance

Excellent corrosion resistance

Higher material costs

Suitable for critical applications

Nickel-Filled Polymers

Magnetic properties addition

Good corrosion resistance

Moderate conductivity levels

Specialized application focus

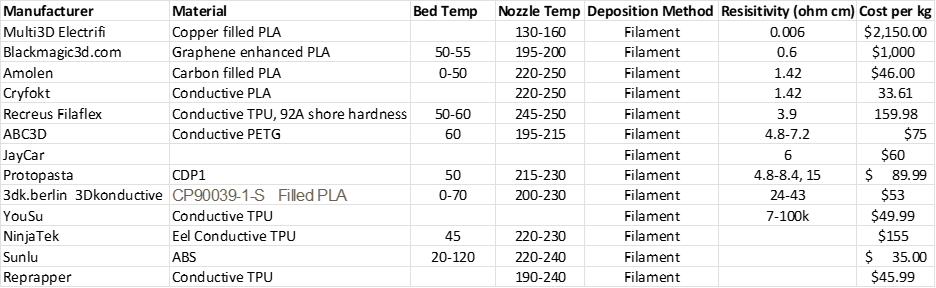

Some of the conductive filaments available today are shown in the table below:

Table: Comparison of Conductive 3D Printing Filaments and their resistivity and cost

The Copper option in Multi3D is the only one approaching the resistivity of conventional electronics. You do need to consider also that Metal composites can be brittle, expensive, and oxidize over time and at high printing temperatures (Cu). In general, filament materials are not as conductive as copper wire or metal traces, but they’re useful for low-power circuits, sensors, and touch devices, EMI shielding, antistatic housings, ESD safe parts, enclosures, and wearable sensors. Improved resolution can be achieved through inkjet or other non-contact tools rather than filaments. Alternatively, paints can be applied to the surface of the part with materials such as Pedot:PSS, graphene inks, silver inks, or metals electroplated on the surface. Below, we show some silver traces that were printed with a syringe tool.

Advanced Polymer Composites

Recent developments have focused on creating more sophisticated conductive polymer composites. Researchers have developed polypropylene filaments with 40 wt% carbon black, achieving enhanced thermal stability and excellent low-temperature flexibility while maintaining high conductivity. These materials unlock applications in organic electrochemistry and electrosynthesis previously impossible with aqueous-limited systems.

Carbon nanotube-enhanced filaments represent another significant advancement. A local enrichment strategy for CNT-filled PLA filaments has demonstrated electrical conductivity improvements of approximately eight orders of magnitude compared to conventional composites.

Metal-Based 3D Printing Materials

Pure Metal Printing

Several companies now offer pure metal 3D printing capabilities specifically for conductive applications:

Copper: EOS and Markforged offer >99.8% pure copper materials for high thermal and electrical conductivity applications

Silver: Advanced silver-based materials with thermally stable silver-organic complexes achieve conductivities up to 55.71 S cm⁻¹

Aluminum: Liquid metal printing systems can produce aluminum parts with excellent conductivity for large-scale applications

Metallic Gels and Inks

Innovative approaches include metallic gels that combine micron-scale copper particles with liquid metal alloys. These materials can achieve up to 97.5% metal content, providing high conductivity while enabling room-temperature 3D printing.

Resin-Based Conductive Materials

For stereolithography (SLA) and digital light processing (DLP) printers, conductive resins have been developed using various approaches:

Silver-filled resins: Containing up to 70 wt% silver-coated copper flakes, achieving conductivities up to 1000 S/cm without sintering

Graphene oxide resins: Utilizing transparent graphene oxide that converts to conductive reduced graphene oxide during post-processing

Polymer composite resins: Based on dendritic copper particles and carbon nanotubes for optimized conductivity and printability

Conductive Inks and Pastes

Direct-write printing systems utilize specialized conductive inks:

Silver nanoparticle inks: Achieving conductivities up to 9.72 × 10⁴ S cm⁻¹ with low-temperature sintering at ~110°C

Copper-based inks: Utilizing copper oxide precursors with reductive sintering for cost-effective high-conductivity applications

Flexible conductive elastomers: Combining silver, carbon nanotubes, and PDMS for stretchable electronics

Printing Technologies and Considerations

Fused Filament Fabrication (FFF/FDM)

The most accessible technology for conductive 3D printing uses standard desktop printers. Key considerations include:

Orientation Effects: Longitudinal printing provides lower resistivity due to conductive path alignment

Layer Adhesion: Critical for maintaining electrical continuity between layers

Print Temperature: Higher temperatures generally improve conductivity but may cause material degradation

Nozzle Compatibility: Some highly conductive materials may require upgraded nozzles

Stereolithography (SLA/DLP)

Resin-based systems offer higher resolution but require careful material formulation:

UV Absorption: Conductive fillers can interfere with photopolymerization

Particle Settling: Requires proper suspension additives to maintain homogeneous distribution

Post-Processing: Often requires sintering or reduction steps to achieve optimal conductivity

Direct Write and Inkjet Systems

Specialized systems enable precise deposition of conductive materials:

High Resolution: Capable of features down to micrometers

Multi-Material Integration: Can combine conductive and insulating materials in single prints

Rapid Prototyping: Ideal for electronic circuit development and testing

Applications and Use Cases

Electronics Integration

Conductive 3D printing enables unprecedented integration of electronics into manufactured parts:

Embedded Circuits: Eliminating traditional wiring and circuit boards

Capacitive Sensors: Touch-sensitive interfaces integrated into product designs

Antennas: Custom RF components optimized for specific applications

Wearable Technology

The flexibility and customization capabilities make conductive materials ideal for wearables:

Smart Textiles: Integration of electronics into clothing and accessories

Biomedical Sensors: Custom-fit devices for health monitoring

Flexible Displays: Conformable electronic interfaces

Industrial Applications

Manufacturing industries benefit from rapid prototyping and custom tooling:

Electromagnetic Shielding: Protecting sensitive components from interference

Heating Elements: Custom-shaped resistive heaters for specific applications

Sensors and Actuators: Application-specific sensing solutions

Research and Development

Academic and industrial research leverage these materials for:

Proof-of-Concept Devices: Rapid iteration of electronic designs

Bioelectronics: Neural interfaces and implantable devices

Flexible Electronics: Next-generation bendable and stretchable circuits

Advantages and Limitations

Benefits

The primary advantages of conductive 3D printing include:

Design Freedom: Complex geometries impossible with traditional manufacturing

Rapid Prototyping: From concept to functional device in hours

Cost-Effective Small Batches: No tooling required for custom electronics

Material Efficiency: Additive process minimizes waste

Integration Capability: Combining structural and electronic functions

Current Limitations

Despite significant progress, challenges remain:

Conductivity Levels: Still orders of magnitude lower than pure metals

Reliability: Consistency can vary between prints and over time

Material Costs: Conductive filaments are significantly more expensive than standard materials

Processing Complexity: Often requires specialized equipment or post-processing

Limited Power Handling: Suitable mainly for low-power applicationsFilaments are good for large conductors but not suitable for fine structures. Conductive materials can be deposited with syringe or inkjet tools. These can be conventional metals (silver, nickel, gold, copper) or conductive polymers such as PEDOT:PSS or carbon in graphene, nanotube, or carbon black forms. Graphene is commonly incorporated into a polymer composite (PLA etc.), or in inkjet printable form.