3D Printed Drones

Comprehensive Design Considerations for Modern Drones

A drone’s success hinges on hundreds of interconnected engineering choices. From aerodynamic contours to software safety layers, each decision carries trade-offs in performance, reliability, cost, and regulatory compliance. This in-depth guide synthesizes current research and industry practice to map the design landscape for multirotor, fixed-wing, and hybrid UAVs.

Structural Integrity and Materials

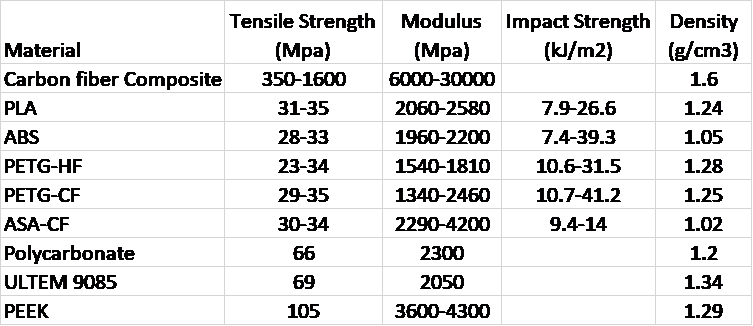

For avionic applications, generally materials need to be very strong (high tensile strength), stiff (high modulus), and lightweight (low density). For this reason, Carbon fiber is a preferred material for the structural regions. 3D printed materials with high toughness are desirable, and when considering that a crash can easily crack conventional PLA or ABS frames. However, one of the advantages of 3D printing is parts can be fairly quickly reprinted and hybrid printing to optimize materials for various functionalities is desirable . ASA and PETG give a good option for superior UV performance, which is important when exposed to the elements. The Table below compares carbon fiber composite to that of most of the common filaments, and more exotic filaments that require high temperature deposition (PEEK and Ultem) and added cost. Clearly Carbon fiber composite has the best strength/weight ratio.

Lightweight rigidity defines endurance. Carbon-fiber frames reach 200–800 MPa tensile strength at <1.6 g/cc density, outperforming aluminum on strength-to-weight. Topology-optimized additively-manufactured arms cut up to 21% mass versus baseline plates while preserving modal stiffness.

Balanced center-of-gravity aligns with rotor plane to damp control effort; modular arms ease field repair and isolate crash loads.

Propulsion System Engineering

Brushless outrunners dominate small UAVs for their high torque and >85% peak efficiency. Optimal KV (RPM / V) lands where required thrust per motor matches propeller-specific power, preventing overstress. Electronic-speed-controllers (ESCs) demand low-RDS(on) FETs and high PWM resolution to minimize switching loss and acoustic chatter.

Redundancy can arise at motor level (coaxial pairs) or vehicle level (hexacopters), trading excess mass for fault tolerance.

Aerodynamics and Flight Performance

Efficient flight begins with clean airflow and the right propulsion geometry. Streamlining the fuselage, tilting arms, or adopting X/T-shaped frames reduces frontal area and drag. Computational fluid dynamics (CFD) or wind-tunnel validation of airflow around rotors confirms lift, thrust, and hover power predictions.

Propeller Geometry

Diameter & Pitch: Larger, lower-RPM propellers raise disk loading efficiency yet enlarge the footprint.

Blade Count & Shape: Bi-blades typically yield lower drag but less thrust authority than tri-blades. Serrated or toroidal tips mute vortices, trimming up to 3–4 dB of tonal noise without lift loss.

Material: Carbon-fiber composites endure high RPM while minimizing flex-induced vibrations.

Multirotor Configuration Trades

NASA analyses show handling qualities and disturbance-rejection bandwidth improve when quadcopters scale to hexa- or octocopters, albeit with mass and cost penalties. Designers iterate rotor count against control authority, redundancy demands, and stowage envelope.

Key design checkpoints:

Energy Density vs Weight: An extra 100 g battery may extend flight 4–6 min but pushes motors closer to continuous current limit.

BMS Intelligence: Cell balancing, over-current, and SOH algorithms avert mid-air failures.

Thermal Pathways: Heat-sinking batteries through aluminum spines mitigates 60 °C pack hot-spots during aggressive discharges.

Control Architecture and Autonomy

Modern flight controllers integrate IMUs, barometers, GNSS, and often vision or LiDAR SLAM sensors.

Safety Layer

Implementation Highlights

Impact on Reliability

Hardware Redundancy

Dual CPU cores or triple modular autopilots with arbitration boards

Maintains control despite single-point CPU failure

Functional Redundancy

Diverse sensor fusion (e.g., GPS + optical flow)

Survives GNSS spoofing/dropouts

Handling-Quality Tuning

Controller bandwidth tuned >0.9 rad/s DRB for urban air mobility

Passenger-grade stability margins

Robust fault-tree analysis (FTA) combined with >19,500 h MTBF autopilot reliability targets reduce latent crash risk.

Safety Systems and Fail-Safe Logic

Regulations increasingly demand no single failure jeopardizes flight. Redundant power buses, “safe-core” flight code, and independent radio links backstop lost-link events. Popular fail-safe modes:

Return-to-Home (RTH): Triggered by GNSS fix + altitude checks.

Land-Now: Autonomous descent on battery reserve threshold.

Parachute Deployment: Required for many >25 kg drones over crowd densities.

Noise Mitigation and Community Acceptance

Urban drone deliveries heighten acoustic scrutiny. Propeller tonal peaks (blade-pass frequency) dominate 70–90 dB hover noise. Solutions:

Serrated Gurney flaps and toroidal loops re-distribute vortices, lowering peak SPL 2–4 dB.

Bio-inspired tip curvatures cut tip-vortex sound without power loss.

Larger, slower props shift energy to <250 Hz, masking high-frequency annoyance.

Microfiber coatings on blade surfaces passively absorb boundary-layer noise at source.

Regulatory Compliance

FAA Part 107 and EASA Specific categories shape design envelopes:

Remote ID: All U.S. UAVs >250 g must broadcast GNSS, altitude, and session ID via onboard module or standard RID-ready airframe. PCB real estate (~20 mm²) and RF shielding must be allotted early.

Weight Classes: Sub-250 g exemptions still demand basic operational compliance but ease registration overhead.

FRIA Operations: Designers for education/hobby should facilitate “non-broadcast” modes within geofenced FRIA boundaries.

Environmental Robustness

PCB conformal coatings, IP-rated seals, and desiccant vents protect avionics from humidity or sea-salt ingress. Wide-temperature lipo chemistries (-20 °C to 55 °C) and self-heating algorithms keep packs within safe electrochemical windows.

Payload Integration and Modularity

Stable imagery demands low-frequency frame vibrations (<60 Hz peak) via grommets and balanced motors. Swappable payload bays (e.g., gimbal vs LiDAR) with quick-release rails expedite mission turnover while managing center-of-mass shifts.

Maintenance and Lifecycle Economics

Rapid-replace arms (bolted rather than press-fit) cut field downtime. Health-monitor telemetry—cycle-counted batteries, motor bearing vibration spectra, and ESC temperature logs—feeds predictive maintenance frameworks, extending fleet life.

Application-Specific Design Notes

Mission Profile

Primary Design Drivers

Typical Configuration

Racing

Thrust-to-weight >8:1, <250 g AUW, 1–3 min burst endurance

5-inch quad, LiPo 6S

Aerial Cinematography

Low vibration, <60 dB hover, smooth gimbal isolation

X8 octocopter, Li-ion hybrids

Survey & Mapping

45-60 min endurance, RTK GNSS, multispectral payload

VTOL fixed-wing hybrid

Package Delivery

>5 kg payload, redundancy, Remote ID compliance

Hexacopter with parachute

Passenger eVTOL

Level-1 handling qualities, DAL-A software, multiple redundant rotors

8–12 rotor tilt-electric

Holistic Design Workflow

Mission Definition: Payload, range, environment.

Preliminary Sizing: Thrust-to-weight, battery capacity, frame scaling using empirical guidelines.

CFD & FEA Loops: Iterate aerodynamic and structural models until power and stiffness converge.

Component Selection: Motors, ESCs, batteries balanced through thrust-stand data.

Control Law Development: Stability margins validated via hardware-in-the-loop benches.

Safety & Compliance Review: Redundancy, Remote ID, EMI, and weight audits.

Prototype & Test: Flight-test envelope expansion under telemetry-rich logging.

Iterate: Design loop revisits earlier stages based on empirical performance gains.

In developing your own Drone, you will need several components:

ComponentFunctionFrame: The physical body of the drone.

Flight Controller: Controls motors, acceleration, and balance.

Motors: Sends rotational power to the blades.

ESCs: Regulates motor speed and direction.

Propellers: The spinning blades that generate lift.

Battery: The power reservoir.

Power distribution board: Supplies power to different parts.

Transmitter:The remote control method.

Sensors:Modules to carry out specialized tasks,such as a camera or infrared sensor.

Optional Functionality: Thermal Cameras

Raspberry Pi or Nvidia Jetson: The brain that ties all hardware and software components together important for more complex control and monitoring.

Low Latency/high resolution camera tradeoffs.

Conclusion

Designing a high-performing, regulation-ready drone involves balancing aerodynamics, structures, propulsion, energy, control, and safety within mission constraints. By methodically applying the considerations and trade-offs detailed above—supported by modern simulation, test data, and evolving standards—engineers can craft UAV platforms that are efficient, resilient, and accepted in increasingly crowded skies.