Most Common 3D Printing Materials

Outline: Below, we outline some of the most popular materials for 3D printing. Also follow the links for focused pages on various types of material below.

Understanding Different 3D Print Materials:

Filament-Based Materials for Rapid Prototyping

Common base polymers for 3D printing Plastic Material

Composites

High Strength

Flexible Materials

Conductive Materials

Support Materials

Sustainable and Recycled Materials

Resin Materials for DLP Printing

Summary

Plastic 3D Printing Materials:

3D Printing, also known as Additive Manufacturing, deposits layer by layer and uses a variety of materials depending on the printing method and desired outcome. The most widely used 3D Printing technology is Fused Deposition Modeling (FDM), which primarily employs thermoplastic filaments.

In general, PLA is the most common 3d printing material as it is easy to print, relatively inexpensive and works well without a heated bed or enclosure. This is followed by ABS for FDM (Fused Deposition Modeling) printers due to their ease of use and affordability. PLA is biodegradable and easy to print with, while ABS is more durable and heat-resistant. PETG offers a good balance between ease of use and durability. Each material has its properties, strengths, and suitable applications. In production for very low-cost parts injection molding is often used. However, in low quantities, Additive Manufacturing is more cost-effective as high-cost molds are not needed.

Here's an overview of common 3D printer filaments:

-

PLA Filament has become one of the most common materials for 3D printing because it is easy to print, biodegradable, and derived from corn and other biomaterials. It prints at relatively low temperatures (190-220°C) with minimal warping, making it ideal for beginners.

Key Properties:

Print temperature: 190-220°C

Bed temperature: 20-60°C (optional)

Low shrinkage and warping, and minimal odor

Biodegradable under industrial composting conditions

Good surface finish and detail reproduction

Limited heat resistance and durability

Ideal for prototypes, low-wear toys, and decorative items when 3D Printing Plastic Material.

-

Enhanced PLA Variants

An improved formulation of standard PLA that offers significantly better mechanical properties while maintaining the ease of printing.

Improvements over standard PLA:

3-4x higher impact resistance

Improved layer adhesion

Better temperature resistance (up to 70°C vs 50°C for standard PLA)

Less brittle, more durable prints

Similar printing parameters to standard PLA

-

ABS is another common 3D printing filament. ABS offers superior mechanical properties compared to PLA, with better impact resistance and higher temperature tolerance. However, it requires more careful temperature management and produces fumes during printing.

Key Properties:

Print temperature: 220-260°C

Bed temperature: 80-110°C

Higher impact resistance than PLA

Better temperature resistance

Can be acetone-smoothed for glossy finish

Durable and heat-resistant

Suitable for functional parts, automotive components, and electronics housings

-

PETG combines the ease of printing similar to PLA with the mechanical properties closer to ABS. It's chemically resistant and food-safe when properly printed. (Plastic water bottles use this type of plastic)

Key Properties:

Print temperature: 220-250°C

Bed temperature: 70-80°C

Chemical resistance

Food-safe applications

Crystal clear transparency available

Combines ease of use with durability

Good chemical resistance and water-resistant properties

Used for food-safe containers, mechanical parts, and outdoor items

-

Recommended when you need it to have good outside performance exposed to UV (durability and weather resistance).

Key Properties:

Similar to ABS but with better weather resistance

Ideal for outdoor applications and automotive parts

Inherently weather-resistant

Excellent UV stability

Chemical resistance to environmental exposure

Print temperature: 240-260°C

Bed temperature: 90-110°C

No post-processing required for weather resistance

-

Nylon can be sourced with different chain lengths and is desirable for its high strength and high heat resistance.

Properties:

High strength and durability

Good chemical resistance

Self-lubricating properties

Print temperature: 240-280°C

Bed temperature: 80-120°C

Requires dry storage and controlled humidity printing

High strength-to-weight ratio and durability

Good for functional prototypes, tools, and end-use parts

Can be challenging to print due to hygroscopic nature

-

Engineering-grade thermoplastic known for its exceptional impact resistance and transparency.

Properties:

Print temperature is higher temperature: 270-310°C

Bed temperature: 90-120°C

Extremely high strength and impact resistance

Excellent optical clarity

Temperature resistance up to 140°C

Requires enclosed chamber and heated bed

High heat resistance

Used for engineering applications and protective gear

-

Flexible material available in waterproof formulations for seals, gaskets, and other flexible applications. There are different variants with a range of shore hardness. 98A is relatively stiff, but the most easily printed and suitable for multi-material printing with systems such as an AMS (automatic material system) for changing materials/colors in a multi-material multicolor print. There are also compositions that include foaming functionality, where printing at higher temperatures and/or slowly will yield a softer shore hardness, such as TPU AIR.

Key Properties:

Flexible and elastic material

Excellent for creating shock-absorbing components, phone cases, and wearables

Characteristics:

Flexible and elastic

Waterproof when properly printed

Excellent abrasion resistance

Print temperature: 210-250°C

Slow printing speeds required

Shore hardness typically 85A-95A

Thermoplastic Elastomers: This involves many elastomers other than TPU. One example is Ninjaflex.

Composites

-

(Cellulose + PLA) Filament is a high-strength highly robust material made from wood fiber and typically PLA. It has the look, feel, and even the smell of natural wood.

PLA mixed with wood fibers for a wood-like appearance and feel

Suitable for decorative items and prototypes

-

Silky texture

-

PLA with metal powder for a metallic look and feel

Heavier than standard PLA, used for decorative pieces

-

Specifically engineered for applications requiring high toughness and impact resistance.

Properties:

Exceptional impact resistance

Reduced brittleness

Maintains easy printability

Ideal for tools, fixtures, and mechanical parts

-

Professional-grade PLA with enhanced strength and durability characteristics.

Features:

Superior tensile strength

Improved flexibility without sacrificing rigidity

Better UV resistance

Enhanced thermal properties

Suitable for functional prototypes

Carbon Fiber Composite Materials

-

LA reinforced with carbon fiber particles for enhanced strength and stiffness.

Characteristics:

Significantly increased stiffness and strength

Reduced weight compared to solid plastic

Matte, professional finish

Requires hardened steel nozzle due to abrasive nature

Print temperature: 200-230°C

-

ASA (Acrylonitrile Styrene Acrylate) reinforced with carbon fiber for outdoor applications requiring UV resistance.

Benefits:

Exceptional UV resistance

High strength-to-weight ratio

Excellent surface finish

Temperature resistance similar to ABS

Print temperature: 240-270°C

Bed temperature: 90-110°C

Ideal for automotive and outdoor applications

-

The combination of polycarbonate's impact resistance with carbon fiber reinforcement.

Properties:

Exceptional impact resistance

High temperature resistance

Professional appearance

Print temperature: 280-320°C

Bed temperature: 100-130°C

Requires enclosed heated chamber

-

Item description

-

Item description

-

Carbon fiber reinforced PETG offering enhanced properties while maintaining chemical resistance.

Features:

Improved mechanical properties over standard PETG

Chemical resistance maintained

Professional matte finish

Print temperature: 230-260°C

Bed temperature: 70-90°C

-

Better mechanical properties than PETG

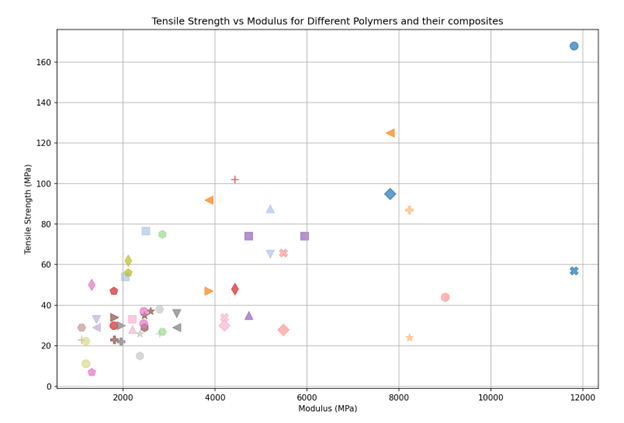

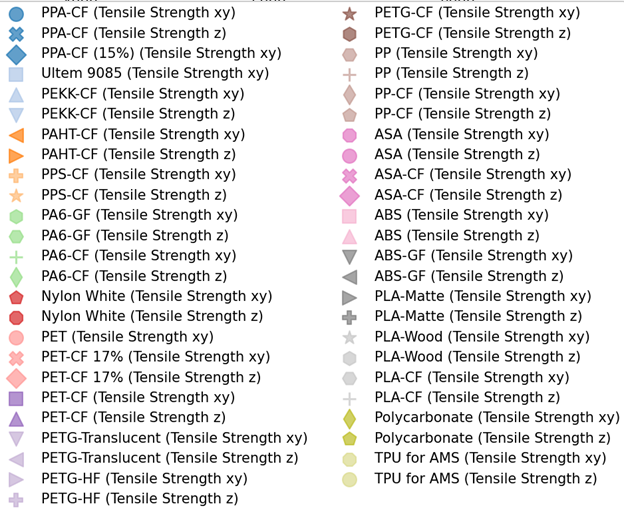

As can been seen on the figure above, PAHT-CF and PPA-CF have very impressive tensile strength and moduli. PET-CF is stronger than PETG-CF

Common materials used in injection molding

-

Chemical-resistant thermoplastic with excellent water resistance and flexibility.

Properties:

Completely waterproof

Excellent chemical resistance

High fatigue resistance

Very low density (floats on water)

Print temperature: 220-250°C

Bed temperature: 90-110°C (with adhesion aids)

Challenging to print due to poor bed adhesion

-

DescriChemical-resistant plastic commonly used in containers and marine applications.

Features:

Completely waterproof

Excellent chemical resistance

Food-safe applications

Very challenging to print (poor adhesion)

Print temperature: 220-260°C

Requires specialized bed preparationption text goes here

3D Print Materials aren’t all in filament form. There are many Resins used for SLA (Stereolithography) and DLP (Digital Light Processing) printers with a wide range of material properties

Resin (for SLA/DLP printers):

Provides high detail and smooth surface finish

Various formulations for different properties (tough, flexible, castable)

Metal powders (for SLS/DMLS printers):

Used for creating functional metal parts

Materials include aluminum, titanium, stainless steel, and more

Ceramic powders:

For specialized applications in industries like aerospace and medical

Each material has its unique properties, strengths, and weaknesses, making them suitable for different applications. The choice of material depends on the specific requirements of the project, such as mechanical properties, environmental resistance, biocompatibility, and post-processing needs.

Material Selection Summary

For Beginners:

Start with PLA or PLA+

Consider PETG for more demanding applications

Avoid high-temperature materials until experienced

For Functional Parts:

ABS or ASA for temperature resistance

Nylon for wear resistance

PETG for chemical resistance

Carbon fiber composites for strength

For Outdoor Applications:

ASA for UV resistance

PP for marine environments

Carbon fiber ASA for structural outdoor parts

For Professional/Industrial Use:

PEEK for ultimate performance

PEI for aerospace applications

PPSU for medical devices

PC for impact-critical applications

Printing Considerations

Nozzle Requirements:

Standard brass nozzles: PLA, PETG, ABS, ASA

Hardened steel nozzles: Carbon fiber materials, abrasive filaments

Ruby or sapphire nozzles: Extreme abrasive materials

Printer Requirements:

Entry-level printers: PLA, PLA variants

Mid-range enclosed printers: ABS, ASA, PETG, Nylon

High-temperature printers: PC, PEI, PEEK

Industrial printers: All materials with proper setup

Storage Requirements:

Hygroscopic materials (Nylon, PVA, PETG): Dry storage essential

Standard materials (PLA, ABS): Cool, dry storage recommended

High-performance materials: Vacuum storage often required